Anatomy of a decentralized water treatment system

removing arsenic, fluoride, organic chemical contaminants, and microbial pathogens

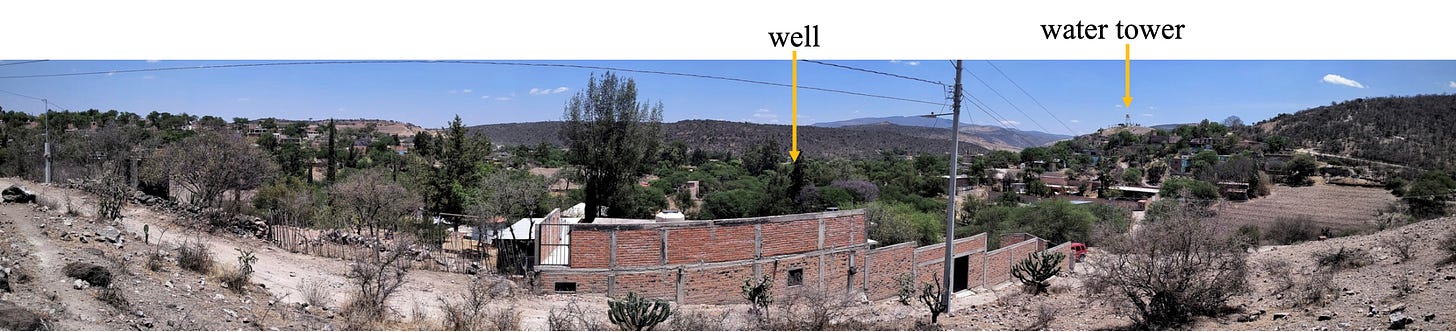

This is the village of Alonso Yáñez, home to around 270 households (about 1,000 people).

The water source for Alonso is a groundwater well (280 meters depth) that contains moderate levels of arsenic (7-8 μg/L) and high levels of fluoride (up to 5.5 mg/L). The Mexican standards for fluoride and arsenic in drinking water are 1.0 mg/L (recently lowered from 1.5 mg/L) and 10 μg/L (recently lowered from 25 μg/L), respectively. Caminos de Agua has set stricter objectives for treated water, however: 0.7 mg/L for F and 5 μg/L for As. Our decentralized treatment systems are designed to meet these tougher standards.

Alonso’s water is pumped from the well located in the valley floor (not visible in photo above) to an elevated water tower. From there it is gravity fed to homes, the school, churches, shops, and to the brick building in the foreground of the photo above, where the treatment system is located.

Alonso’s water receives no treatment other than chlorination at the wellhead at irregular intervals. It is supposed to be chlorinated all the time, but the responsible parties show up maybe every few months to dose chlorine. (Typical for rural communities throughout the region.) The treatment system building is at the far end of the distribution system, and rarely if ever receives water with a chlorine residual. This is probably the case for many/most of the households as well.

The people of Alonso either drink the untreated groundwater, or purchase bottled water in 20 L carboys for 50 pesos (a little less than US $3 at current exchange rates) from commercial providers (subsidiaries of multinational corporations such as Pepsi, Coca Cola, Nestle, etc.).

Beginning April 20, 2024, the people of Alonso Yáñez will be able to purchase treated water for 20 pesos per 20 L carboy (around US $1.15).

Concurrent with the initiation of this project to provide treated drinking water, an international team of researchers working with the Mexican National Institute of Public Health are carrying out an epidemiological study to monitor health effects in school children in Alonso. The team includes a dentist who performs regular dental exams of the children to monitor for dental fluorosis as an indicator of fluoride exposure, and a doctor conducting regular physical exams and collecting urine samples for monitoring of biomarkers indicating kidney stress from arsenic exposure.

Intake station at the grade school in Alonso that coordinates physical and dental exams of students and sample collection. Left-to-right: Camille Zimmer (Center for Affordable Water and Sanitation Technologies, CAWST), me, health study project leads Paulina Farias (Mexican National Institute of Public Health) and Prof. Marcela Tamayo-Ortiz (Columbia University), Marcio Botto (CAWST). Camille and Marcio were visiting with me and Caminos this week to explore forming and R&D collaboration between CAWST and ourselves to work on chemical water contaminants.

The epidemiological study will provide data showing the benefits of water treatment on children’s health and development. This will motivate municipal and national authorities to provide more support for implementing decentralized water treatment infrastructure.

I will report on the epidemiological study in more detail in later posts. For now I want to describe the design specifications of our treatment system.

A multi-barrier approach to providing water that is Estético, Seguro, y Saludable (Pleasant, Safe, and Healthy)

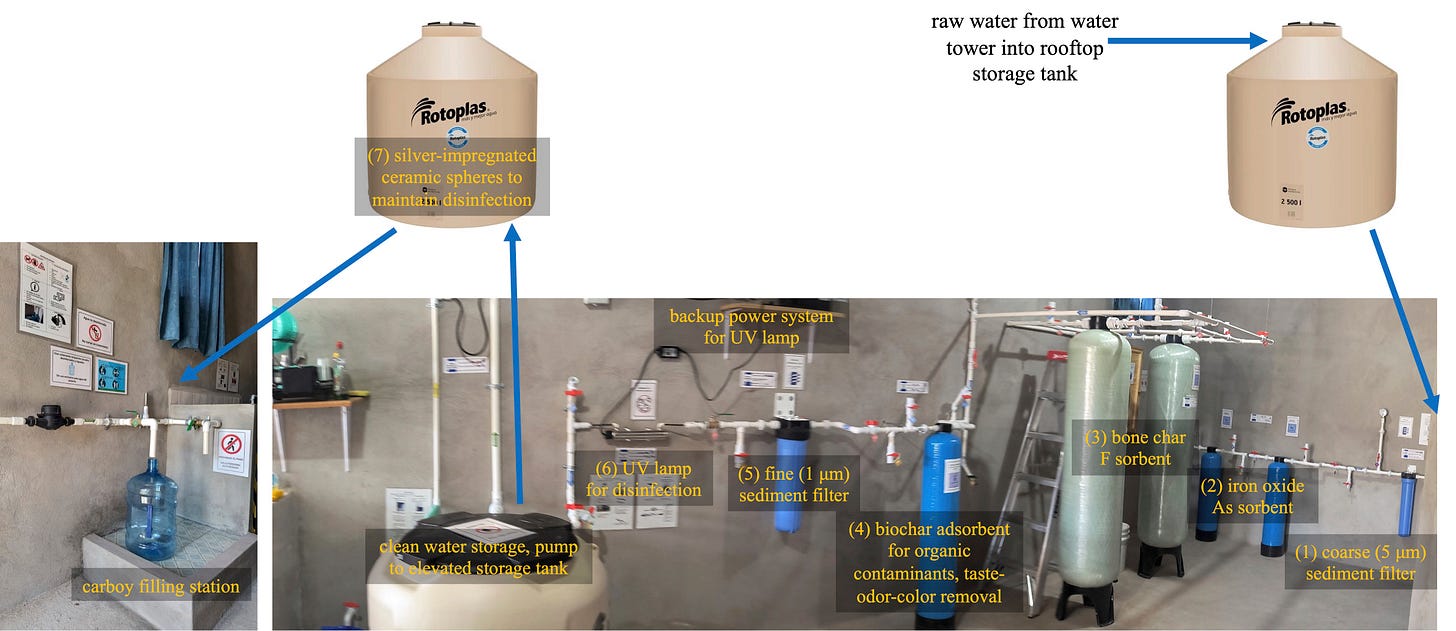

Water moves through the treatment system as shown in the photo be from right-to-left:

Raw water arrives by gravity from the village water tower to a storage tank on the roof of the building where the treatment system is housed. It is then gravity-fed through several sequential treatment steps:

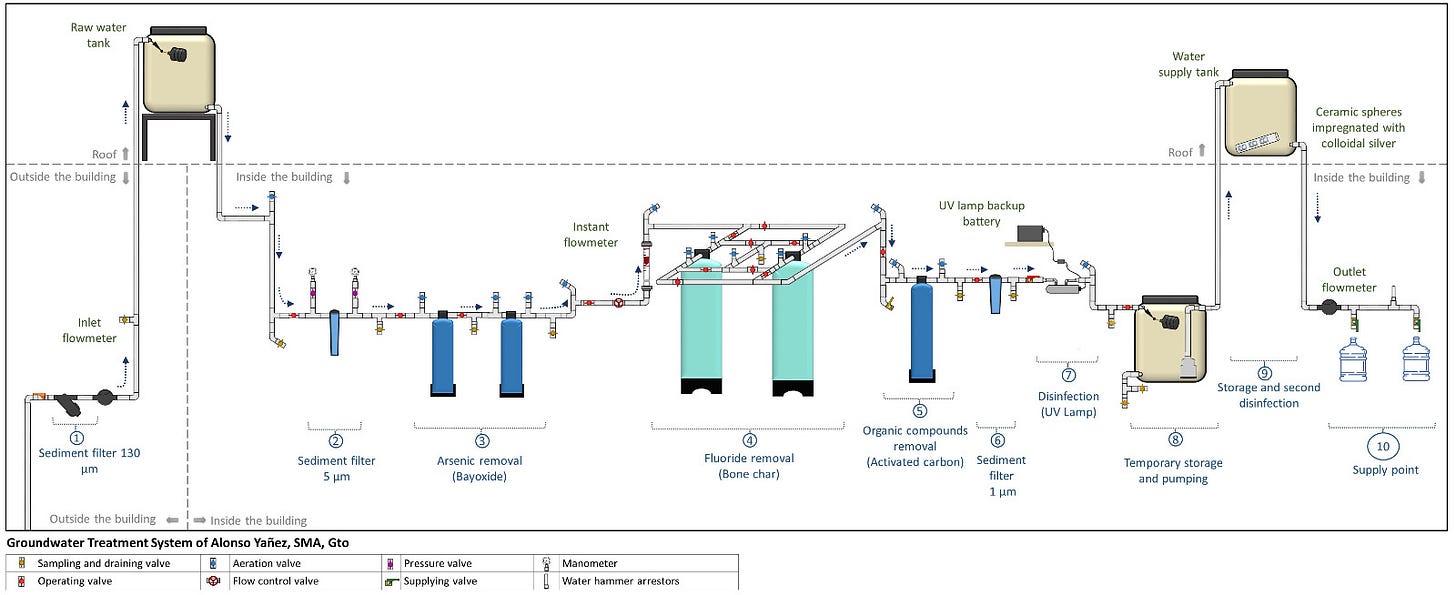

A coarse (5 μm) sediment filter to remove particulates.

Two columns containing commercial iron oxide sorption media (Bayoxide E33) for As removal. The two columns are operated in lead-lag fashion to maximize sorbent utilization. Because the As concentration is relatively low, and because the iron oxide media has such a large capacity for As uptake, the As columns are modest in size. They are easy for one person to move around when swapping lead and lag columns, replacing the sorbent, etc.

Two (large!) columns containing bone char sorbent for F removal. The bone char columns are also operated in lead-lag mode for optimal sorbent utilization. Because the F concentration is high and bone char’s capacity for F uptake is moderate, the bone char columns have to be very large. This precludes them being easy to move around by one operator. The manifold shown above the bone char tanks (white PVC piping and valves) is designed so that lead-lag column swapping can be done by adjusting valves rather than having to physically move the tanks.

Biochar (or activated carbon) contactor for control of organic chemical micropollutants and improvement of water aesthetics. The carbon adsorbent column has three main purposes: (1) removal of pesticides or other chemical micropollutant contamination that might be present, (2) removal of color, taste, or odor associated with the raw water or introduced by the bone char, (3) removal of disinfection-by-products or other chemical pollutants that might somehow contaminate the source water and that would trip drinking water regulations and necessitate one or more rounds of very expensive water testing to maintain system permits by regulators.

A fine (1 μm) sediment filter to remove any fines, for example particulates released by the sorption media. Suspended particles would also reduce UV transmittance (the next step) and so need to be removed…

UV lamp for disinfection. A batter backup power supply is installed to keep the lamp on in the event of a power outage of the village’s electrical grid (common). Since the treatment system operates by gravity, if the electricity is off the system still produces water. So power backup is necessary to ensure continuous UV disinfection.

The water is pumped from the clean water storage tank inside the building to an elevated tank on the roof to achieve the head necessary to rapidly fill carboys at the carboy filling station. The rooftop storage tank contains ceramic spheres impregnated with colloidal silver to maintain a disinfection residual during storage.

The eighth treatment step is not shown in the above diagram because it happens in the homes of water customers. Customers fill up their carboys at the treatment plant and transport them home for consumption. It’s possible that during transport or home storage the water could become recontaminated with microorganisms, for example if their transport carboy or storage container are not clean. Therefore, to become part of the water co-op, customers have to purchase a ceramic filter home treatment unit and undergo a training to ensure safe water transport and storage in the home.

Ceramic filter units manufactured by Caminos de Agua. The ceramic is impregnated with colloidal silver for antimicrobial activity. Ceramic filters can be installed in a bucket setup or into the neck of a carboy atop a decorative base as shown.

Training water system customers in Alonso how to assemble, use, clean, and care for their home filter units.

Project Costs

Here’s a treatment system schematic showing a bit more detail than then photo-diagram above, including pressure gauges, flow meter, water hammer relief units, etc.:

To give you an idea of project costs, the materials that make up the treatment system come to about US $8,000. This includes two additional bone char contactors (not shown in the photo or diagram) that will be added to the system as the customer base expands.

This does not include construction costs to the building, which have totaled about US $3,500. The building is a community center and the part where the treatment system is located had to be fully closed in and finished. So these costs were for modifying and finishing an existing structure.

Caminos de Agua also incurred very substantial costs - about US $10,000 - in water testing and validation for regulatory purposes. Some testing was done in-house but the majority of analytics were outsourced to a commercial lab, which is very costly. All of this was so that they could obtain permits from the regional water authority to sell treated drinking water.

Building construction and permitting/water testing costs will of course vary in a site-specific way. So to just focus on the materials and equipment costs of the treatment system (i.e., what is shown in the diagram above), here are some relevant details:

The design capacity of the system is 2,700 L/day (so for a village of 270 households, 10 liters per household per day).

In order to buy water from the system, as stated above households need to buy a ceramic filter home unit and undergo a safe water transport and storage training. They purchase a carboy for 40 pesos (about US $2.40) and a ceramic filter/bucket unit for 475 pesos (about US $28). These prices are subsidized 50% by Caminos (normal retail prices are 80 pesos and 950 pesos for the carboy and filter/bucket unit, respectively). The subsidy is to reduce the barrier for families who want to buy water from the system but can’t afford to pay full price.

So far, out of the 270 households, 92 households have completed the safe water training and are so are qualified customers. Caminos of course expects this to grow, ideally reaching all 270 households.

Starting with a customer base of 92 households, Caminos will charge 20 pesos (about US $1.20) per 20 L carboy (so 1 peso/L). Based on their estimates, this will cover running costs of the system. As the customer base grows they hope to drop the price to 15 pesos per carboy (about US $0.90 per carboy or about US 4.5 cents per liter) and still cover system running costs.

So overall per-person costs (in US dollars) come to

up-front costs of about $8 per person in treatment system equipment and materials, plus about $8 per person for the carboy and ceramic filter/bucket home treatment unit

and running costs of about $0.12 to $0.16 per person per day (about $45 to $60 per person per year) to purchase drinking water. (Plus the ceramic filter unit should be replaced after three years of use, so figure about another $0.60 per person per year to cover that.)

So as a rough conservative estimate, providing “Pleasant, Safe, and Healthy” drinking water to the citizens of Alonso Yáñez incurs up-front costs of about $20 per person and running costs of about $60 per person per year. (This doesn’t include costs for construction or modification of a building to house the treatment system, our water testing, inspections, and other compliance costs to satisfy local regulatory bodies.)

And if it weren't for the high levels of fluoride (>5 mg/L) in Alonso’s groundwater, costs associated with water provision could be reduced substantially. Fluoride treatment turns out to be a major cost-controlling variable…

The elephant in the room (bone char/fluoride treatment)

By far, the biggest cost factor - for both up-front and running costs - is the bone char. Alonso Yáñez’ well with a fluoride concentration of 5+ mg/L F, might be at the upper limit of cost feasibility for bone char treatment. Value engineering this step is absolutely crucial. I alluded to this in a previous post, but this topic is getting A LOT of attention and I will be writing more detailed posts on this topic in the future.

For an estimated cost of US $10 per kilogram, just the bone char costs $3,000 out of the overall system equipment and materials cost of $8,000. That’s nearly 40% of the total up-front costs, just for the bone char.

And that’s only a rough estimate since we don’t have good cost figures for the bone char. We are using bone char produced by Caminos using a method that we develop as detailed in the supplementary information of this research paper.

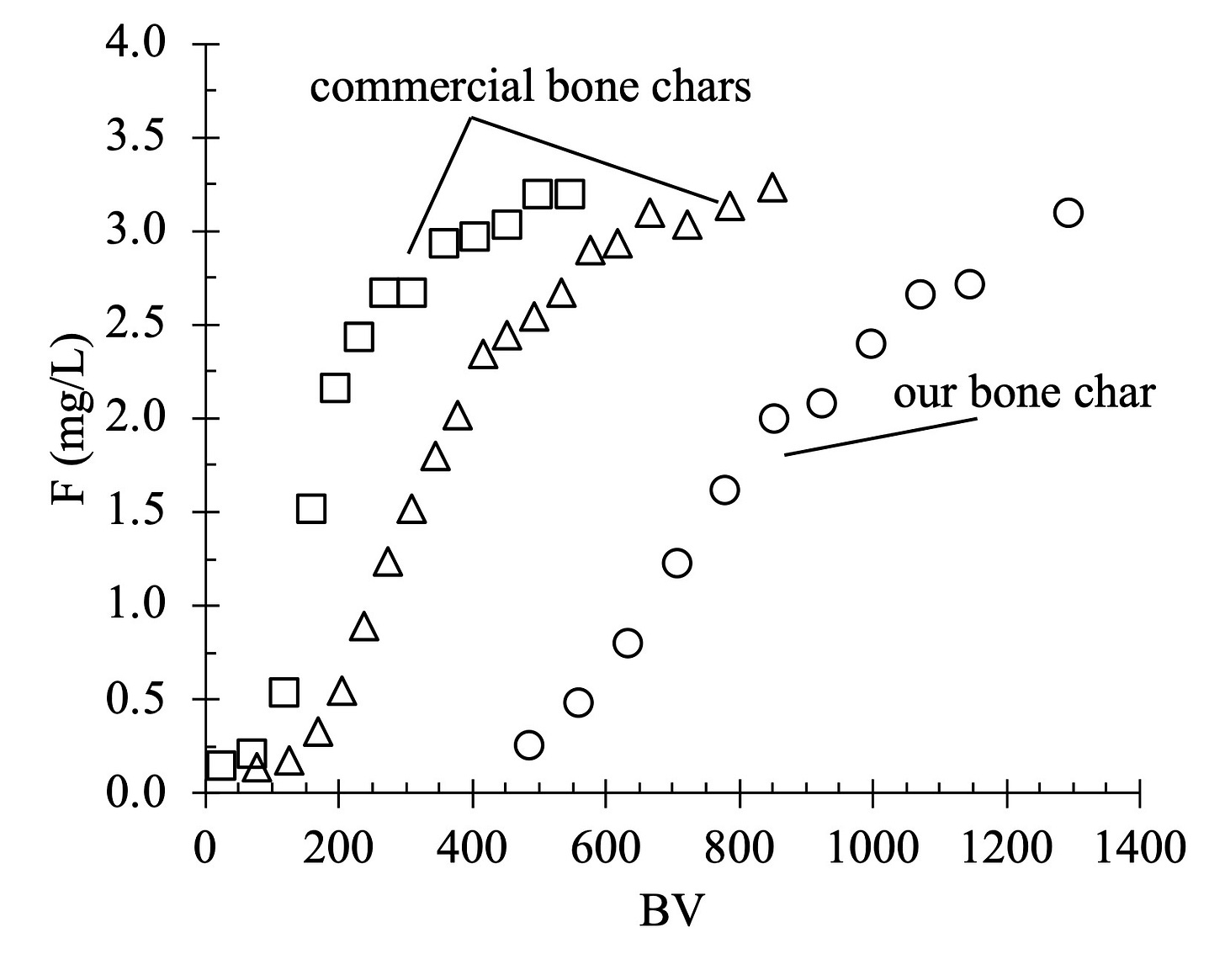

Commercial bone chars are available for purchase. Here’s the problem:

These are the results of column testing we conducted comparing our bone char with two of the best commercially available bone chars. For groundwater at pH 8-8.5 containing 3.6 mg/L F, we were able to treat about 585 bed volumes before reaching the treatment objective of 0.7 mg/L F. Whereas, the commercial bone chars were only able to treat 210 bed volumes and 100 bed volumes before reaching 0.7 mg/L F, respectively.

This illustrates the point that bone char cost per kg is not so important as bone char cost per treatment capacity.

Caminos doesn’t want to be in the bone char manufacture business. But for the time being we have to be, since the commercially available alternatives are not cost effective due to their much lower F uptake capacities. We have started a collaboration to design and pilot a scaled-up bone char manufacture process that we hope will become a profitable business in its own right. I’ll write more about that collaboration later. For now I am using $10/kg as a best-guess at what a price point could be for our high performance water treatment bone char. In truth we won’t know the exact price until we have our manufacture process up and running and optimized.

In addition to comprising a significant proportion (i.e.., ~40%) of up-front costs, the bone char also occupies a major portion of running costs. Since it’s so expensive (or rather, since so much of it is needed in the treatment system), it makes no sense to regard it as single-use. Luckily, bone char can be regenerated. (Future posts of course will be dedicated to describing our bone char regeneration R&D.) Due to the high fluoride levels in Alonso Yáñez’ groundwater, we estimate that the bone char will need to be regenerated monthly! The logistics and labor will be significant, to say the least.

Even so, Caminos estimates that they will be able to provide drinking water for around 4.5 to 6 cents (US) per liter and cover the running costs of bone char regeneration along with other system maintenance.

I’ve written enough for now to give a thumbnail sketch of the project in Alonso Yáñez. The experience really drives home how much of a bear fluoride treatment is! As you can see very well, the bone char unit process dominates the economics and feasibility of the treatment system. The other unit process don’t figure nearly so significantly into the overall cost structure.

Optimizing bone char production, optimizing it’s integration with other unit processes, and optimizing its regeneration are among our foremost R&D challenges! Any breakthroughs here will have MAJOR impacts for combatting this devilishly difficult water contaminant.

And considering that something like 180 million people worldwide suffer from excessive fluoride levels in their groundwater, solving these challenges could represent a miracle for global public health!

Global risk map of fluoride in groundwater in excess of 1.5 mg/L. Note that 1.5 mg/L is the World Health Organization Guideline Value. Mexico recently lowered their standard to 1.0 mg/L, and Caminos de Agua’s treatment objective is <0.7 mg/L. A lot more of the map above would turn yellow, orange, and purple if 1.0 or 0.7 mg/L were used. Source: Podgorski, J., Berg, M. Global analysis and prediction of fluoride in groundwater. Nat Commun 13, 4232 (2022).

You don’t need to use bone char for fluoride removal since the bone char is just creating more solid waste. You can reversibly use adsorbents that can transfer the fluoride in the water to a usable product such as Calcium Fluoride, and the adsorbent can be used indefinitely.