Value engineering bone char for fluoride removal

quick pause for a glance at multiple works-in-progress

I still haven’t found the magic formula that permits me to simultaneously work productively and write about working productively. I seem to only be able to either “do stuff,” or “write about doing stuff,” but not both at the same time. But I will keep trying…

For the moment I am hitting pause in order to highlight some of the flurry of activity over recent months. I/we am/are so grateful to the readers and supporters of this site. Please feel free to reach out with questions, feedback, criticisms, requests, etc.

We’re building a laboratory

You read that right, we are building a laboratory. Much of my February and March were consumed with site preparation. The site where the lab/workshop will be built was previously occupied by a run-down-beyond-all-hope single-wide mobile home. It had to be removed before construction can begin.

I’m not one to waste anything. So rather than demo the trailer and have the wreckage all hauled off to the dump, we painstakingly gutted it down to a salvageable stick frame-and-roof and then repurposed it.

One grungy old single wide trailer became five mobile livestock shelters for our local regenerative rotational grazing operation. If you’ve been a reader here for a while you will be familiar with our decentralized, grassroots, ecological approach to water and sanitation provision. Our “frugal innovation” philosophy in the WASH sector extends in a completely congruent fashion to other dimensions of building regenerative economies and sustainable human settlements under resource constraints and on a tight budget. If you’re interested to learn more about our agrarian initiatives, check out the free Magpie Hollow Farm newsletter.

Once we get further into the lab/workshop build I will write at least one dedicated article with lots of photos detailing the project.

Value engineering bone char

For today I want to highlight the R&D project alluded to in the title of this article.

I’m currently in central Mexico working with the brilliant and capable tech team of Caminos de Agua. We’re bringing online a new community treatment system that has all the bells and whistles - bone char for removal of excessive fluoride, iron oxide for removal of arsenic, biochar for control of organic chemical contaminates and organoleptics (taste, odor, appearance), microbial pathogen control barriers, the works… There’s also a team of public health researchers here kicking off a long-term observation project to document the health benefits of communities receiving water treatment. I’ll write up an article describing that project in more detail later.

For now I just want to highlight one of the main hurdles to cost-effective fluoride control using bone char. In short, in regions where fluoride (F) in groundwater is a problem, F levels tend to be high (e.g., >1 mg/L); and although bone char is one of the most effective methods available for controlling F, its F sorption capacity is relatively low.

This means that, in qualitative terms, bone char contactors need to be large and the bone char needs to be replenished often. Because of this, bone char/F unit processes tends to be one of the more costly components of a comprehensive water treatment system.

Keeping costs as low as possible therefore requires value engineering bone char/F systems. Practically, this means optimizing bone char production processes to favor increasing F uptake capacity as much as possible, as well as finding ways to regenerate (remove sorbed F) and reuse bone char (rather than treating it as single-use for disposal).

We have ongoing R&D efforts in optimizing bone char production and regeneration processes. I’ll write more about these in the future. Right now I want to show some exciting recent experimental results indicating how biochar (i.e., char made from non-bone biomass such as wood) can be used to bolster the efficacy of bone char/F treatment.

Here are the important points:

Bone char produced at lower pyrolysis temperature (i.e., 400-500 C) has substantially higher F uptake capacity than bone chars produced at higher temperature (600-700 C).

Above ~700 C, calcination reactions take place that alter the bone mineral structure, and its F sorption capacity falls off a cliff to effectively zero.

FYI, you can recognize this super-overcooked bone char since it turns white, whereas normal water filter bone char is black.

Here’s a sample of bone char used in a column test to quantify F uptake. The white specs are “overcooked” bone char that has very little F sorption capacity. Overall, this bone char sample did not perform well for F removal, since it had been exposed to too-high pyrolysis temperatures.

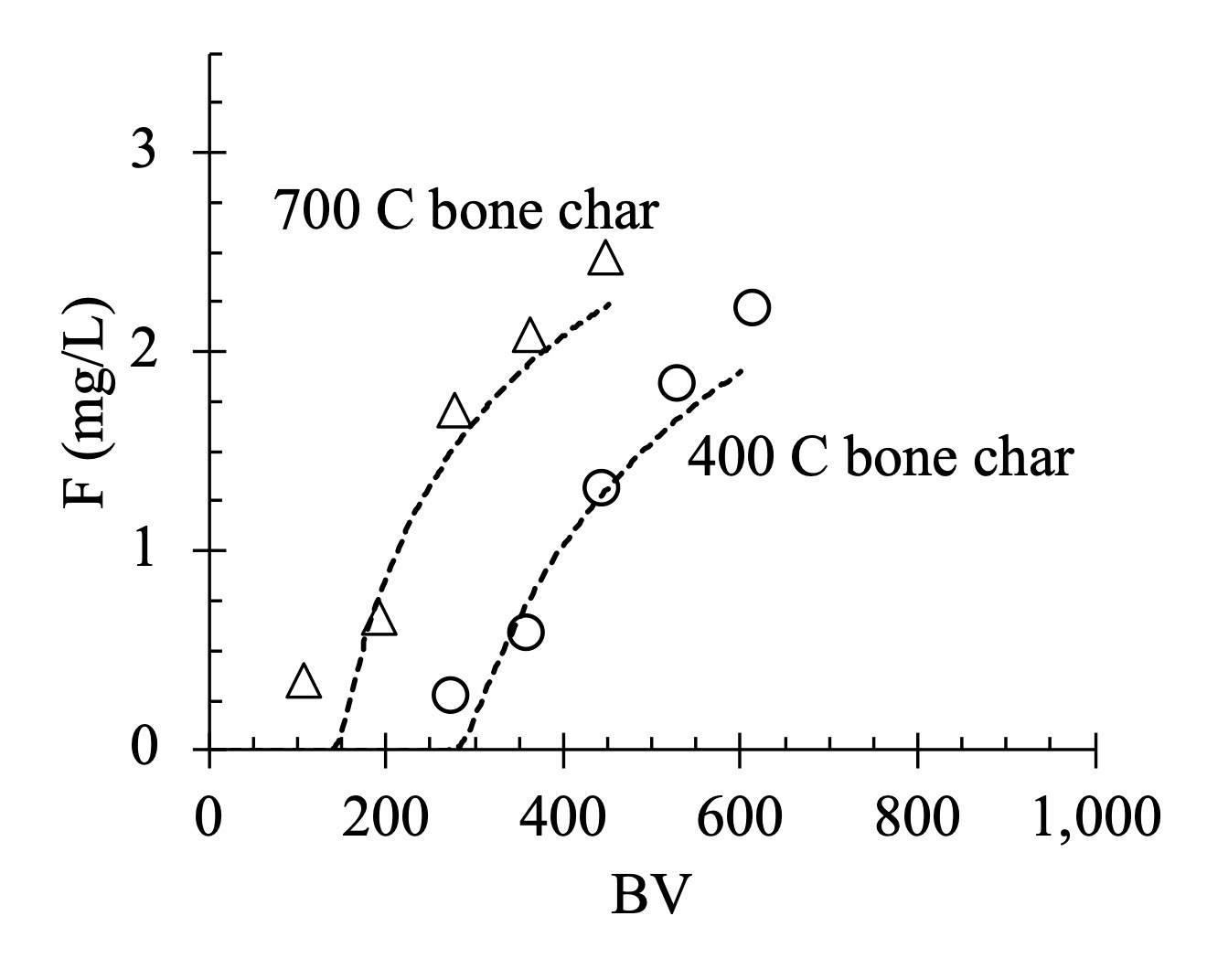

Results from Rapid Small Scale Column Tests (RSSCTs) using bone chars generated at 400 C and 700 C treat groundwater containing F at 3.5 mg/L. The 400 C bone char exhibits twice the F removal capacity of the 700 C bone char. The dashed lines represent sorption model fits to the data (open symbols).

The problem with low temperature bone char is that some of the organic phases within the char are “undercooked.” These phases can leach out into water, leading to taste, odor, and appearance (i.e., organoleptic) problems. The water looks yellowish and tastes and smells like burnt BBQ, in other words. Yuck!

Here’s where biochar comes in.

Our hypothesis was that biochar could be used after low temperature bone char to remove organic leachates that cause unappealing organoleptics.

If this works, then a biochar “cleanup” step could allow us to take advantage of the much-enhanced F uptake exhibited by bone chars made at ~400 C.

Since the bone char/F unit process is such a major cost factor in water treatment, even adding an additional biochar “cleanup” step might still be overall cost-effective.

One important question is how to quantify potentially problematic leachates from bone char. This is the subject of our ongoing R&D efforts and deserves its own separate post(s). For now, I’ll just state without explanation that fluorescence offers us a powerful and relatively inexpensive (and portable for fieldwork) tool to track these substances.

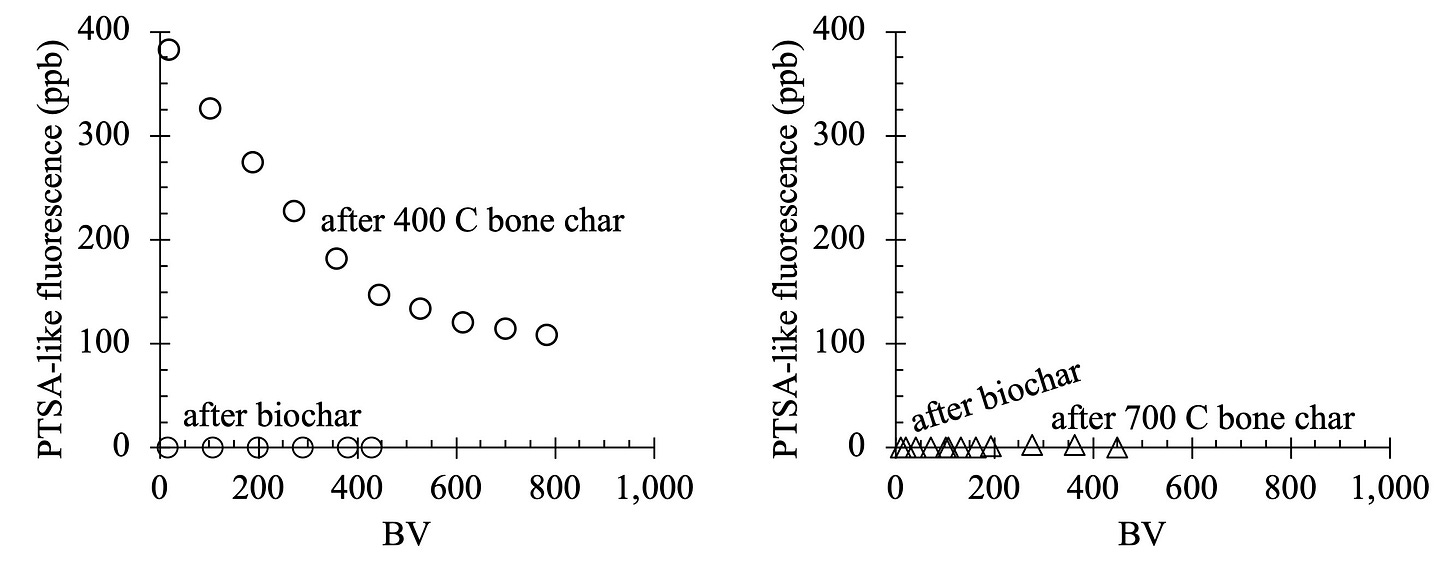

Results from RSSCT experiments using bone chars generated at 400 C (left panel) and 700 C (right panel), followed by biochar. Fluorescence monitoring indicates high concentrations of potentially problematic organoleptic compounds released from 400 C (i.e., “undercooked”) bone char. 700 C bone char did not release compounds at concentrations detectable by this method, consistent with their transformation into well-carbonized, non-soluble forms adhered in the bone char. The left panel indicates that fluorescent leachates produced by the 400 C bone char were removed below detection level by the biochar.

The exciting result here is that biochar was very effective for removing potentially problematic organoleptic compounds detectable by this fluorescence method.

This research may allow us to shift our bone char pyrolysis to optimize F removal capacity while counteracting organoleptic problems introduced by low temperature bone char. Overall this could translate to a great cost-effectiveness benefit for bone char/F treatment.

Cool!

I’m pleased to be able to offer you this tidbit from our recent research, as a sampling of all the stuff we have going on and forecast of interesting article topics to come.

I really am going to do better about getting research and fieldwork updates out. I appreciate your patience and ongoing enthusiasm and support for our work!

Why bone char? Activated charcoal from wood would be less hassle, no?