Establishing a decentralized water treatment social enterprise in Ecuador

new biochar and water quality testing capabilities, and an advanced course for core team members

Last month I reunited with friends/coworkers in Lago Agrio, in the Amazonian region of northeastern Ecuador.

Luis and Lexie at Amisacho.

Our goal and the focus of my visit is to elaborate a new model of decentralized water treatment service provision in the region.

Last year we held a workshop that was attended by about 60 people mostly from the northeast region of Ecuador but from other parts of the country as well. In that workshop, which you can read about here, we offered a conceptual and hands-on training in the bare-bones, Do-It-Yourself (DIY), from-scratch methods of setting up water systems using local materials.

The DIY-from-scratch approach is something we have taught dozens of times in very low resource settings in Thailand, Burma, Sri Lanka, Mexico, and now Ecuador. It’s well suited to austere and remote circumstances where local materials and simple hand tools are all that is available. It’s labor intensive and not necessarily the most efficient process, but it can be done start-to-finish by hand, and even without the need for electricity.

Some of our trainees from last year took up the challenge, and held work parties in their home communities - for example in the very austere conditions of Afro-Ecuadorian settlements.

In Ecuador as in all our project areas, there seems to be a growing demand for tiered options of decentralized water treatment services. In the most challenging and resource-constrained settings - such as in refugee/IDP camps and the temporary settlements of people in very insecure conditions - the labor intensive DIY-from-scratch approach might be the only option. But what about slightly better-resourced communities? Is there a way to streamline the provision of water treatment services - to make the process more efficient in terms of time, labor, and materials, and keep costs down while offering design, implementation, and monitoring services as a small business employing local water technicians?

We’re going to answer this question through a pilot project in Lago Agrio. My visit last month was to kick off this new initiative.

Our ongoing activities fall into three categories:

Streamlining the production of biochar adsorbent

Equipping the field lab with biochar and water quality testing capacity

Training the core team to function as technical water consultants

Streamlining production of biochar adsorbent

One of the most labor intensive steps of setting up decentralized water systems is making and processing the biochar adsorbent. Once a suitable local biomass feedstock is identified, it has to be processed - typically chopped to a uniform size and shape for the gasifier/pyrolysis reactor and dried, charred with adequate temperature/time intensity, and then processed to the desired granular particle size by grinding, sieving, and washing.

There are huge opportunities for improving the labor and materials efficiency throughout this process. For example, the waste heat given off during pyrolysis/gasification can be redirected for other useful purposes such as drying feedstock. Biochar crushing and sieving to obtain the desired size fraction can be greatly assisted by the use of small machinery. Taking advantage of these potential efficiencies and economies of scale is facilitated by centralizing where appropriate and optimizing the scale of different process steps. What constitutes the “best” or optimal overall arrangement depends a lot on location specific variables.

So, thinking along these lines, Luis has been prototyping a mobile (trailered) modified kon tiki style kiln to make biochar out of scrap wood from local carpentry shops.

Scrap wood - such as faulty broomsticks as shown here - is burned in open piles near carpentry shops.

We made temperature observations during charring using a standard square pyramid kon tiki design kiln, and found that conditions were not hot enough to generate effective biochar adsorbent. So we modified the design by cutting out the bottom and replacing it with a grate to induce high airflow through the kiln:

Modified kon tiki biochar kiln.

That worked to achieve high temperatures! No problem getting to 1,000 C or more - we even destroyed a few thermocouple probes in the process.

Modified kon tiki - hot hot hot!

Based on that preliminary work, Luis and I decided that (1) we need a mechanism to exert control over the draft and temperature, (2) we need to scale up to make bigger batches, and (3) what if we took the kiln to the feedstock and hauled the biochar home, rather than hauling mountains of feedstock home to the biochar kiln?

With that in mind, he fabricated the prototype for the kon tiki loco: a mobile high-temperature kiln that can accept a variety of feedstocks for making biochar adsorbent.

Luis, looking like he is up to some kind of mischief.

For draft control, he put in a false bottom with a metal pipe port that can be connected to a blower.

He added removable jacks so that the wheels can be removed and the kiln lowered onto the ground for use.

Step one is to load the kiln with feedstock until a thick bed of biochar coals is formed inside. Then step two is to crank up the blower so that the whole coal bed glows red hot, achieving high temperature (~1,000 C) semi-aerobic gasification conditions needed for making effective adsorbent are achieved. Step three - water quench.

Here you can see a super-heated zone in the bottom of the kiln causing the metal to glow a faint red, visible even in daylight hours.

From the first trial run: we could have kept going filling up the kiln, but we ran out of feedstock. This thing can make a lot of char per batch!

Removing and reinstalling the wheels is not too difficult and can be accomplished by one person.

The jury is still out whether it’s better to take the kiln to the feedstock, or bring the feedstock to the kiln. There are advantages and disadvantages either way. Luis will continue experimenting to determine an optimal setup given local logistics.

Biochar and water quality testing

After a summer of R&D in my home lab and in collaboration with the brilliant tech team at Caminos de Agua in Mexico, I brought the first iteration of a biochar and water quality testing apparatus to set up in the field laboratory at Amisacho.

Field lab ready biochar column testing equipment - fits nicely into a couple of carry-on sized luggage bags.

In future posts, I’ll describe system components in details and discuss the different test we can conduct with this apparatus, how to analyze the data, and what it all means.

For now I’ll just briefly summarize that this setup allows us to:

compare different biochars and quantitatively evaluate their performance as adsorbents

conduct quality analysis testing on biochar produced in bulk at Amisacho to optimize the production process and assure a consistent product

evaluate different source waters as to their treatability by biochar and assist in source selection

collect data to provide quantitative input to the design of biochar units treating particular source waters; optimize treatment system design for unique biochar-water combinations

provide a quantitative guide to targeted monitoring and evaluation of biochar water treatment installations, saving labor, laboratory resources, and logistics costs

A big focus of my visit was training Luis, Pablo, and Lexie how to set up and run column tests, perform water quality measurements, etc.

Pablo measuring dissolved iron.

Luis loading a biochar small column test.

Alexsandra, lab director at local university ISTEC, tag-team teaching with me as we demonstrate how biochar small column tests work and what we can learn from them.

Capacity building with a core team of technical water consultants

Bootstrapping a decentralized water treatment outfitter and consulting group social enterprise requires a dedicated core team supplied with the right knowledge and experience. For the enterprise to be successful over the long term it needs to *not* depend on me. So my role with the Ecuador project as well as with projects in other locales around the world is shifting away from being a necessary cornerstone facilitator of these projects to tech support and knowledge transfer. I’m engineering myself out of their work, in other words.

Accordingly, a key objective of my trip last month was to work with the local core group to ensure they possess the conceptual knowledge and hands-on experience to be able to:

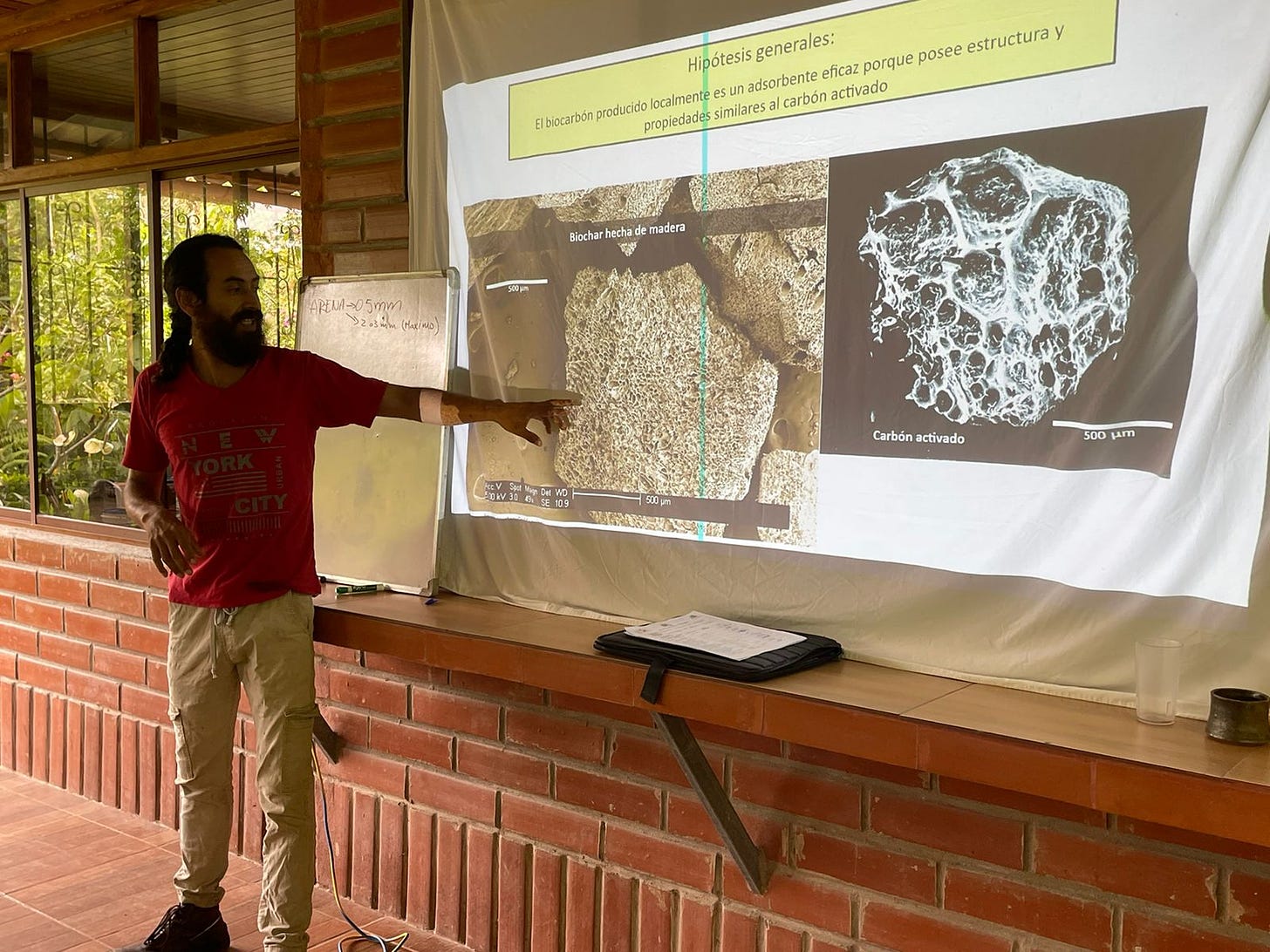

understand key concepts about how adsorption takes place in microporous carbonaceous adsorbents, and how adsorbent physical-chemical properties that favor efficient adsorption arise from biochar production conditions.

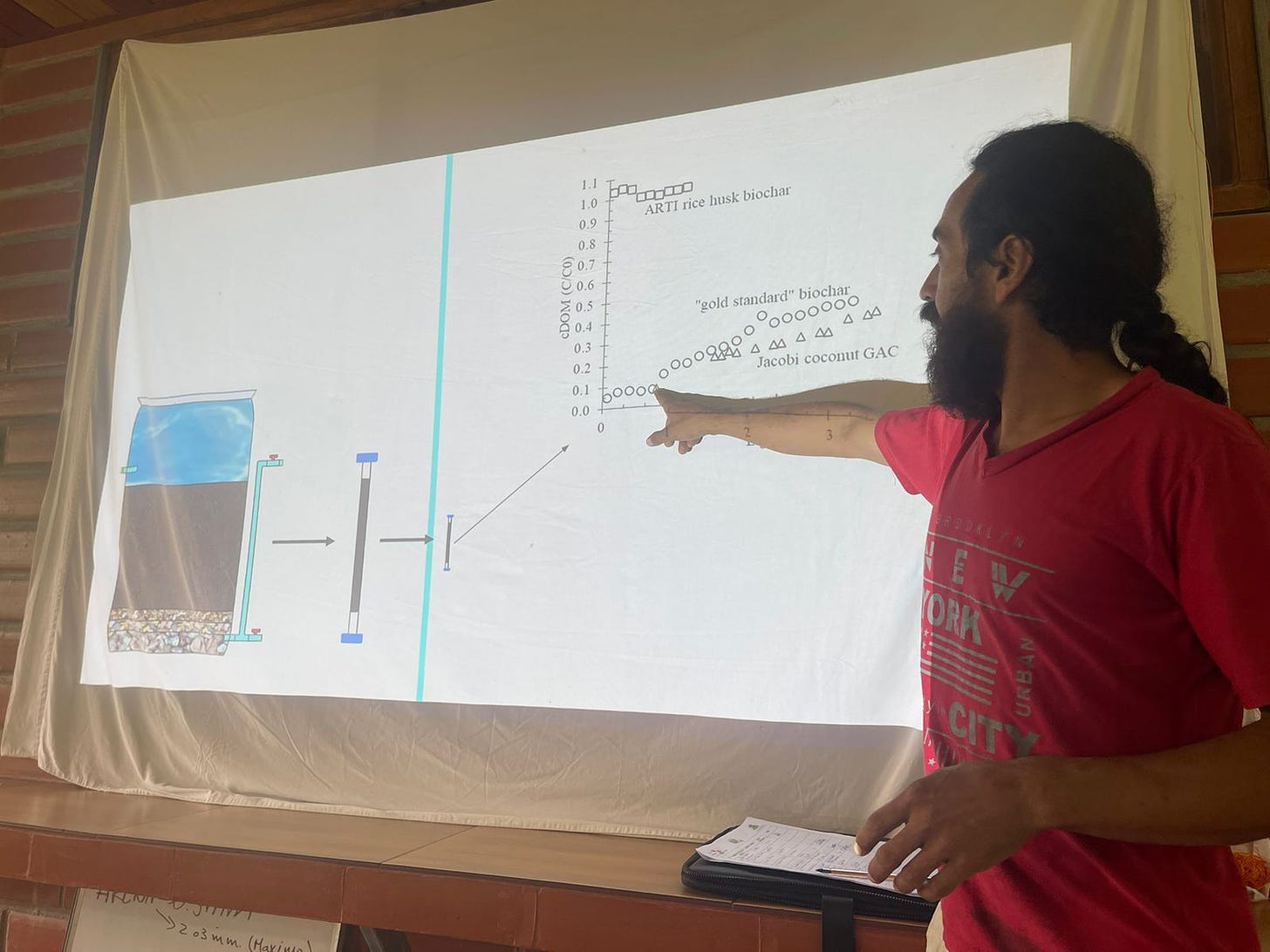

understand the breadth of chemical contamination of water sources, how and why pollutants representing a variety of chemical classes have been selected for in-depth adsorption studies (so called “sentinel chemicals”), and how to interpret and utilize data from these studies in the design of biochar contactors.

understand the pivotal role of background dissolved organic matter (DOM) - how it impairs adsorption of target chemical micropollutants, and how we can leverage DOM adsorption using ultraviolet and fluorescence spectroscopy for field lab analysis of biochar adsorbents and source waters.

carry out biochar adsorbent and water quality tests, and interpret the data from these tests through the lens of biochar adsorption research on removal of chemical micropollutants from natural and anthropogenic source waters.

communicate a holistic view of water quality - considering water aesthetics (taste, odor, appearance), microbiological safety, and healthfulness from a chemical perspective. This is a pedagogical approach to working with community on water projects that we developed during my visit last year, the so-called Estético, Seguro, y Saludable (Pleasant, Safe, and Healthy) framework, soon to be published in a special issue of the journal Water Security.

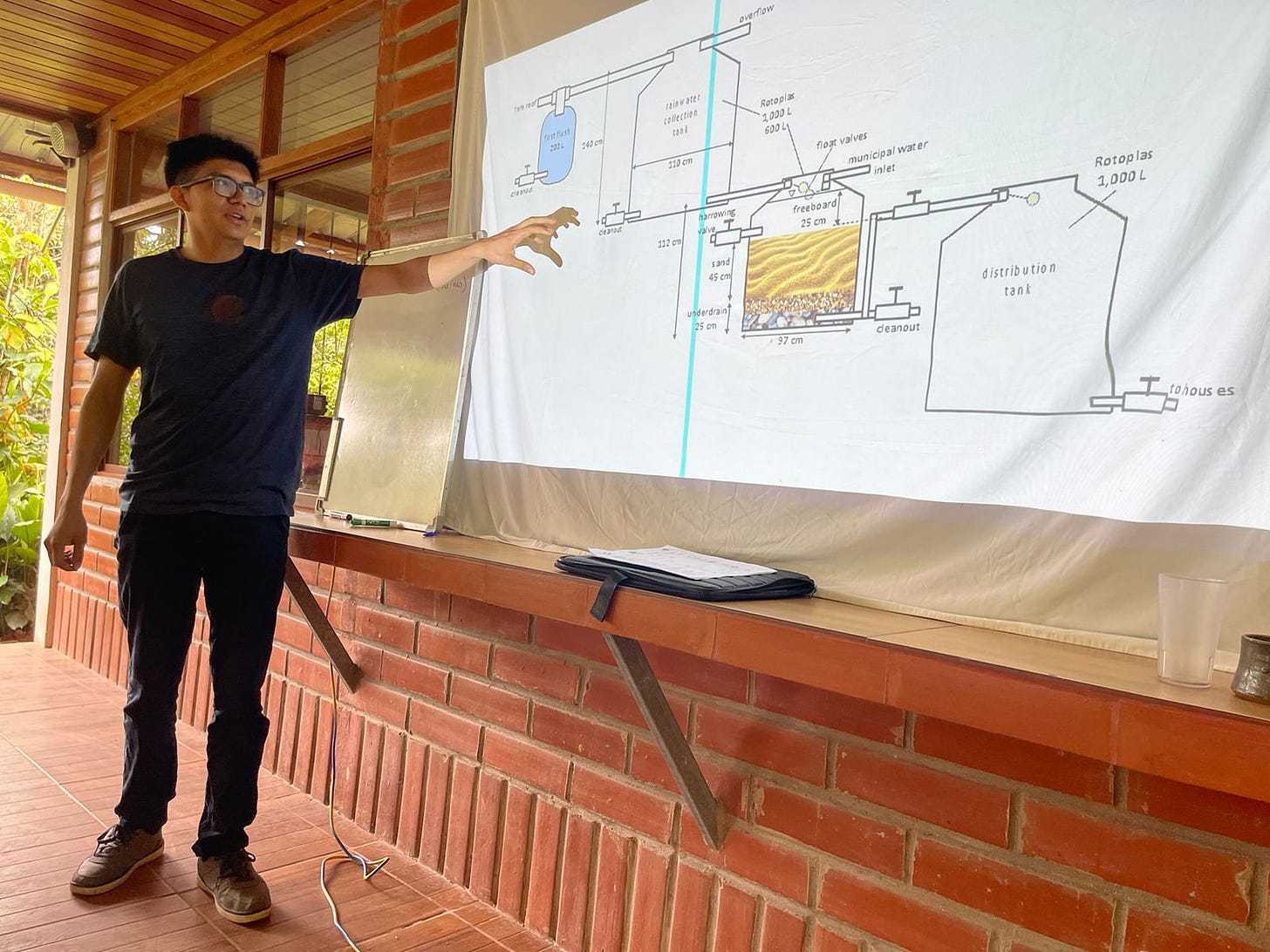

possess working conceptual and practical knowledge of the design, implementation, and operation of a variety of unit processes that can be paired with biochar adsorption to meet the Estético, Seguro, y Saludable criteria, such as roughing filtration and biological slow-sand filtration.

To accomplish this, we held a series of day-long teach-ins with the group of half-a-dozen or so that will form the core of the decentralized water treatment consultancy social enterprise.

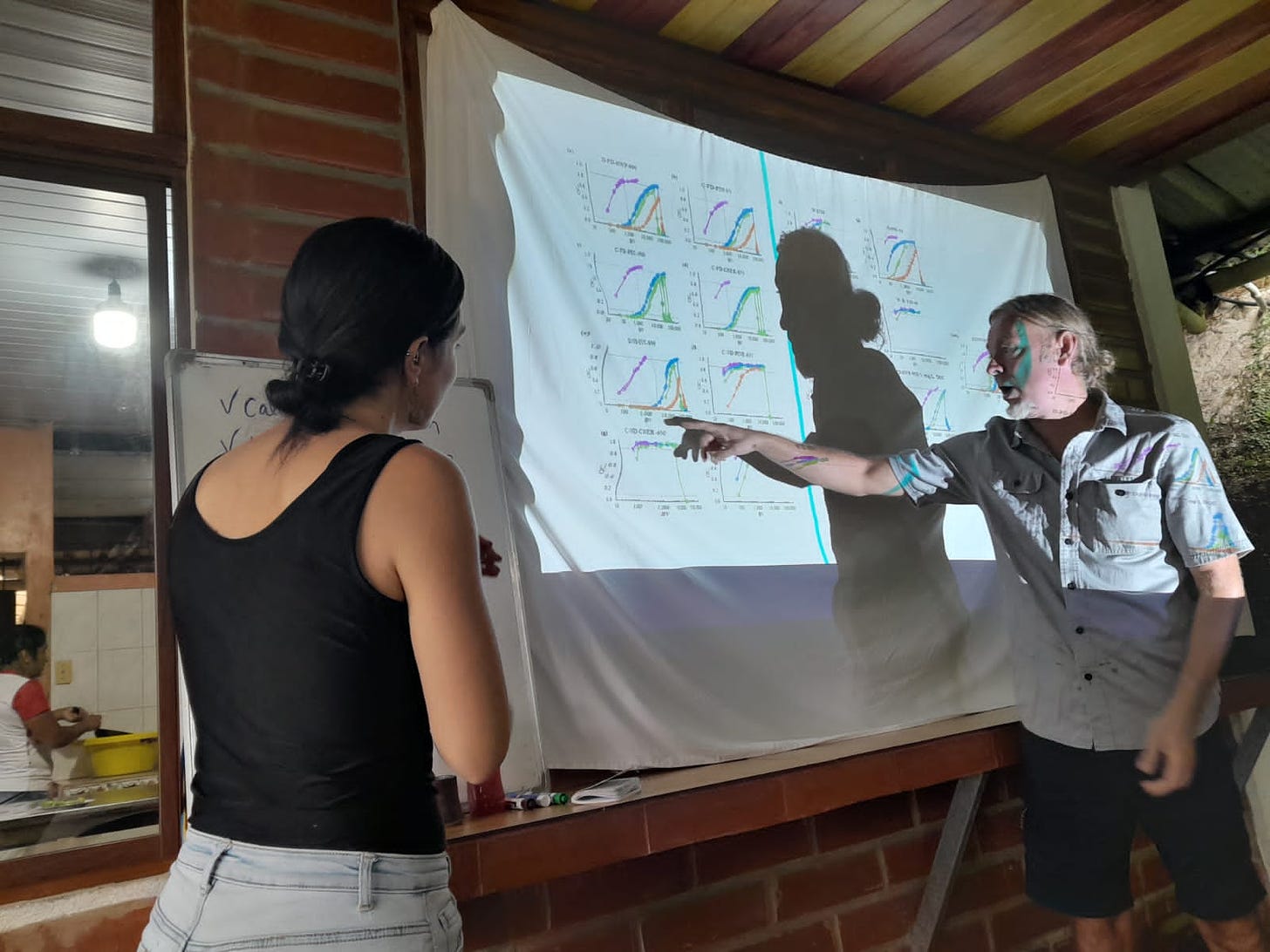

Here I am for example reviewing the giant database we have amassed through our own research and scouring the topical literature of biochar rapid small scale column tests (RSSCTs) and pilot column tests, and explaining how we use these data to inform design and operation of biochar contactors:

Then, near the end of my visit, we invited members of local NGOs and community groups to a half-day workshop to learn about the new consulting facility for water projects my colleagues are forming. Groups in attendance work on a variety of environmental, human rights, and sustainable development initiatives throughout the Amazonian region. Water projects are frequently a component of their work, but they often struggle due to lack of domain expertise. The new center will provide a group of experts they can sub-contract with to ensure quality and sustainability in the water components of their overall work.

The purpose of the half-day event was to showcase the services the new consulting team can offer. They became the teachers and I faded into the background - available for Q&A where necessary. I felt a weird but satisfying kind of gratitude to see how little they needed me!

Pablo explaining adsorption in microporous carbons.

Pablo explaining how RSSCTs represent scaled-down models of real-world contactors, how how we interpret the data from RSSCT studies.

Jose explaining rainwater harvesting and biological slow-sand filtration.

Alexsandra reviewing important classes of chemical water pollutants.

Pablo and Lexie reviewing the mechanisms of pathogen removal in the biofilm of slow-sand filters.

We are grateful for funding support from the Roy A. Hunt family Foundation for this project!

In upcoming posts I’ll drill down into what we’re measuring in these field lab RSSCTs and describe the equipment involved. Basically the point is to bridge the gap between the database of biochar adsorption research generated using advanced laboratory methods like high resolution mass spectrometry - that cannot be duplicated under field conditions - and what we actually can measure using comparatively low cost and portable analytical equipment. Connecting all the links in that conceptual chain is what is going to enable biochar water treatment to benefit so many more people in diverse circumstances around the world!

Great work, I always get a buzz out of reading about the open source teaching you’re doing. I hope all this goodness your spreading comes right back at you too. Thank you!

Good work!