Petrochemical pollution in the Ecuadorian Amazon

A new partnership to innovate and disseminate biochar water treatment in South America

In this article…

Photos, short video clips, and summary of recent workshop activities with communities in the Ecuadorian Amazon affected by petrochemical pollution

Information on a new “kon tiki” kiln design for making biochar adsorbent

Biochar water treatment workshop team: from left, Luis, Pablo, Lexie, JK, and Julia (not shown - the photographer!).

I spent two weeks this September working with two incredible grassroots organizations - Amisacho Restauracion and the Clinica Ambiental - to provide training in biochar water treatment to communities in the Ecuadorian Amazon affected by petrochemical pollution.

The Oriente – the eastern, Amazonian region of Ecuador – has been heavily exploited for decades by the petrochemical industry. Oil pipeline ruptures are common, thousands of petrochemical waste pits dot the landscape, and sooty gas flares burn day and night combusting methane and other gases that are not economical to capture and utilize.

See for example, the documentary Crude:

…and a January 2022 NBC news story on pipeline rupture:

This has caused massive pollution of the Amazonia ecosystem, killed wildlife, and contaminated water sources with a wide range of toxic compounds. Local indigenous populations have suffered a variety of diseases, including cancer and birth defects, from exposure to petrochemicals through drinking water, wild foods such as fish, and bathing in contaminated streams.

gas flares

gas flares and waste oil pit

We conducted a two-day introductory biochar water treatment workshop for 65 attendees from Amazonia and other parts of Ecuador affected by petrochemical water pollution.

classroom-style lecture/discussion sessions on key concepts and theory for using biological slow sand filtration and biochar adsorption to provide drinking water that is safe and healthy

This workshop covered

(1) generation of biochar adsorbent using the TLUD-style drum oven,

(2) preparation of granular biochar for use in fixed-bed treatment units,

(3) preparation of sand and gravel filter media for use in biologically active slow sand filters to remove pathogen microorganisms, and

(4) the combination of biochar, sand filters, and other unit processes for the production of water that is safe (i.e., free from pathogens) and healthy (i.e., free from harmful chemicals) for consumption (drinking and food preparation).

This workshop served as a pilot program for a new water curriculum under development by local partners Clinica Ambiental. The Clinica will host future biochar water treatment training workshops and integrating this work into their broader efforts in agroecology and biodiversity conservation.

Luis explaining the concept of high temperature semi-aerobic pyrolysis for making water filter biochar

loading the drum oven

Crushing, sieving, and washing biochar for water filters

bicycle powered biochar crusher (machine used to separate coffee beens and chaff)

As part of the workshop we also designed and installed a biological slow sand filter to treat rooftop harvested rainwater, with municipal piped water as a backup water source.

washing and sieving sand for biological slow sand filter

In this context, rather than simply installing a traditional “blue barrel” treatment system, it made sense to construct a larger biological slow sand filter to provide water to several households for a variety of tasks - washing dishes, washing clothes, hand washing - and to treat a portion of this water for consumption (drinking, cooking) using point-of-use biochar contactors.

Pablo demonstrates a unit that can be located near the kitchen sink for treating ~30 L/day of water for drinking and cooking.

After the workshop, Luis and Lexi traveled to a few communities to continue teaching and help them set up treatment systems.

Biochar water treatment is spreading rapidly in Ecuador!

Modified kon tiki kiln for generating biochar adsorbent

I also had a chance to work with Luis on a project I have been interested in for a long time.

The kon tiki style biochar kiln has become popular in recent years. I often get asked whether it’s a good method for making biochar adsorbent for water treatment.

I’ve only been able to answer that, “We know the conditions that generate effective adsorbent biochar from working with TLUD (top-lit-up-draft style gasifiers): 850-1050 C, with plenty of air present to drive high temperatures and open up the biochar micropore structure.” Whether the kon tiki is a kiln design that can reliably achieve this conditions has been unknown, at least to me.

Luis and I made a few batches of biochar with the kon tiki he built. Our temperature observations suggested that small zones of the kiln can reach high temperature (>850 C). The upper corners of the kiln can reach these high temperatures since air is being drawn into the kiln to drive combustion. Note the glowing charcoal in the kiln corners shown in these photos:

However, once the newly-formed charcoal is buried, it begins to cool, and continues to cool over the course of the burn to 500 C or below.

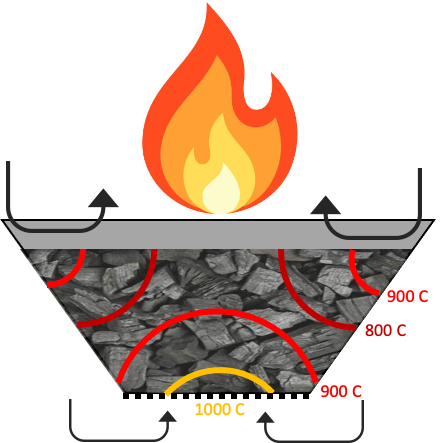

I made this cartoon based on our temperature observations to illustrate approximate thermal zoning in the char bed of the kon tiki kiln:

The black arrows indicate how air draft is drawn into the upper corners of the kiln.

The idea Luis and I came up with for a prototype modified kon tiki design was simply to cut out the bottom of the kiln and replace it with an expanded metal grate - the same material we use in the bottom of the TLUD-style drum oven kiln to promote sufficient primary air draft.

modified kon tiki

We thus created a kind of hybrid TLUD-kon tiki design, with the aim to achieve thermal zoning something like illustrated here:

The goal was to introduce sufficient air through the bottom of the kiln to maintain the char bed at high temperature for the duration of the burn.

It certainly got hot! We provisionally named this design the kon tiki loco!

Our temperature observations indicate success!

Temperature profiles of biochar generation in unmodified (blue) and modified (red) kon tiki. In both cases the feedstock was reject broomstick wood. The added aeration in the modified kon tiki facilitated superheating, known to produce enhanced biochar microporosity, pore connectivity, and pollutant adsorption capacity.

We can now say that it’s possible to achieve the aeration and high temperature conditions needed for making biochar adsorbent using a (modified) kon tiki style kiln. The simplest approach is to replace the bottom of the kiln with a metal grate. More flexibility and control could be achieved, however, by installing a shroud and blower on the base of the kiln in order to regulate draft and temperature in the char bed:

Modified kon tiki with a blower to provide controlled draft and heating during pyrolysis.

Next steps for this project including building a larger, mobile (trailer mounted) kon tiki loco to take around to lumber mills carpentry shops, etc., to make water filter biochar from their piles of waste biomass.

In our experiments we used reject broomstick wood. This material can be obtained for free or very cheap from local manufacturers. Normally they just burn their reject broomsticks and scrap in open piles.

There are a lot of opportunities to identify “waste” biomass streams in the Amazonian region - including scraps from lumber mills, carpentry shops, and wood product (e.g., broomstick) manufacturers; agricultural residues from sugarcane, palm fruit/oil, and coconut production.

A mobile modified kon tiki unit with draft control could make use of a wide variety of feedstock types, shapes, and sizes to convert a “waste” stream into a high value economic good to protect human health and the environment.

Aqueous Solutions has partnered with Amisacho and the Clinica Ambientalto raise R&D funds to support a pilot project in biochar generation and water quality testing. We already have one proposal under review! Wish us luck!

Does the grate on the bottom not cause excessive ash production in later stages of the burn? Or do you close it off with mud before that happens?

I typically start my pyramid kiln burns by building a platform of biomass about halfway up in the kiln to ensure very hot burn from the start.

Hi Josh, I changed my kontiki kiln the way you did and tested the char on filtering red raspberry juice as an experiment to my daughter's class. I did not yet measure the temp during gasification but it glowed red and was very hot run. We built the filter in a plastic coca cola buttle, filled with only the crushed char. The juice after filtration became totally transparent and clear water. Another advantage is the option to drink this water and test if sweet taste is left. I can sent you few pictures if you like. Thanks!