I was fortunate to spend two weeks in June working with colleagues at Caminos de Agua on a variety of applied field research projects. In normal (i.e., non-pandemic) times I spend a week or two, three or four times a year working intensively with their brilliant tech team. Like working with the Free Burma Rangers, the Karen Women's Organization, and Pun Pun Centre for Self Reliance, these interactions with Caminos are far-and-away the most rewarding part of my job.

Caminos has an extensive ongoing water quality monitoring program throughout their region of central Mexico. In the watershed surrounding San Miguel de Allende, in the state of Guanajuato, two of the foremost water quality challenges face by poor communities in the campo (countryside) are high levels of naturally-occurring fluoride (F) and arsenic (As).

Screenshot from Caminos de Agua’s interactive water quality map.

In recent decades the high desert lands of Guanajuato have come increasingly under the control of big agri-business. The elevation, climate, low levels of certain insect pests, and lack of enforcement of water withdrawal and quality regulations has spurred a boom in broad-scale production of organic vegetables, in particular water intensive crops like broccoli. A major highway running through the state provides a direct artery north to markets in the US. In fact, the vast majority of crops grown in huge monoculture plantations throughout central Mexico are exported to the US.

An excellent short documentary on water scarcity and quality problems in Guanajuato.

Pumping vast quantities of “fossil water” from deep aquifers has rapidly drawn down the water table, in some zones by as much as one to three meters per year. The situation is unsustainable by any metric you care to choose. Disturbance of the deep subsurface has mobilized fluoride and arsenic that occur naturally in the region’s geology. In the arid climate, deep tube wells are typically the only water source for rural communities. Accordingly, diseases associated with exposure to arsenic and/or excessive levels of fluoride have become common throughout the region.

I’ve been working with Caminos’ tech team for the past several years to develop a low-cost off-grid groundwater treatment system to remove F and As. Part of this work has included construction and testing of a pilot treatment system at Caminos’ rural field lab and teaching facility.

My visit in June coincided with a very special landmark in the project. After nearly two years of design iteration, testing, monitoring, and evaluation, the system was approved for the neighboring community to commence using the water.

Ribbon-cutting ceremony for the new mini water treatment plant, June 2021.

Caminos de Agua’s pilot groundwater treatment system. Water flows from left to right in the photo-diagram.

Groundwater from a nearby tube well is pumped into a 600 L (160 gal) tinaco (tank) on the roof of the field lab building. It gravity-feeds into the building where it passes through a sediment filter, then through two columns (in series) containing granular iron oxy-hydroxide sorbent to remove As, then through two series columns of granular bone char to remove fluoride, then through a biochar contactor to remove any unpleasant tastes or odors as well as trace organic pollutants. The water is then chlorinated to maintain a disinfectant residual and pumped into another tinaco on the roof of the lab. Community members fill up their water containers from a tap located in a fenced-off, protected area on the side of the lab building.

In the photo above you can also see a bunch of ports and valves located above and below the media columns. These are used for taking water samples before and after different treatment steps, and for removing air trapped in the system.

You might ask, Why are there two columns, each, of the As and F treatment granular media?

The reason for this is that we’re interested to quantify how different modes of operation of treatment units can influence, and potentially benefit, performance. In subsequent installments I’ll go into detail about how this works, the math behind it, and how you can put it to work for your application(s). For now, let’s just say there are some engineering tricks you can use to “get more mileage” out of your sorbent that involve running multiple columns in series or parallel configurations. (For those who want to read ahead, see out article in J WASH DEV, “Lead-lag series and staged parallel operational strategies improve the performance and cost-effectiveness of bonechar for control of fluoride in groundwater.” In a forthcoming study we’ll show how you can do the same for As treatment using granular iron oxy-hydroxide.)

For now let’s take a step back and reckon with the level of effort and commitment by the Caminos tech team to set up this system and monitor it over many months for quality assurance as well as research purposes. Under the conditions studied, conducting a monitoring campaign over one life-cycle of one of the bone char contactors shown in the photo above took about three months.

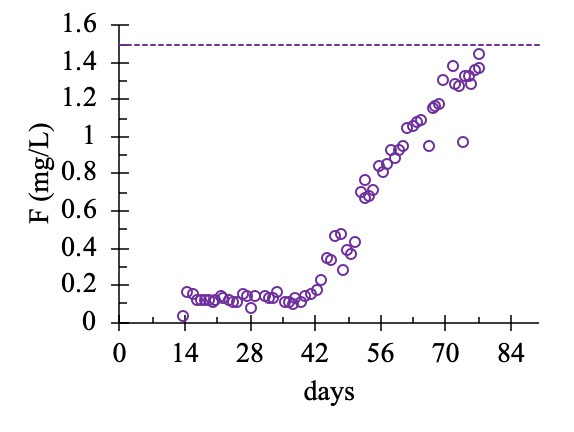

Monitoring data from the lead granular bone char contractor treating groundwater (pH 8.5) containing fluoride (F) at a level of 1.85 mg/L. The World Health Organization (WHO) Guideline Value for F in drinking water is 1.5 mg/L (indicated by dashed line).

What if you could get useful quantitative information about treatment performance much faster? I mean, in the above plot things didn’t even begin to get interesting until six weeks into the experiment. The As/iron oxy-hydroxide data is worse! (Better, from the perspective of the consumer…) A full six months was required before As in the first column effluent exceeded the WHO Guideline (10 ppb).

Enter the Rapid Small Scale Column Test (RSSCT) - a way to simulate the performance of full-sized treatment systems in a fraction of the time and using a fraction of the experimental resources needed for a full-scale monitoring study. Another objective of my June visit was to advance our progress in the development of RSSCT methods tuned to the water quality and treatment challenges faced by the communities that Caminos serves.

To those ends I set up an RSSCT study to determine an accurate approach for simulation of several months of full scale treatment in a little over one week, and using ~15 L (~4 gal) of test water instead of ~25,000 L (~6,600 gal).

Visual comparison of column studies using a full-sized system (left) and a Rapid Small Scale Column Test (RSSCT; right). Full-sized bone char columns, though overall ~1.5 m in height as shown in the photo, contain around 0.5 m depth of granular bone char media. Full scale columns are 8” (20.3 cm) inner diameter. RSSCT tubing shown is 3/16” (0.476 cm) inner diameter.

We introduced the basics of the theory behind the RSSCT back in Chapter 3. In subsequent installments we’ll go into further detail how this method can be applied to simulate treatment performance using a range of sorbents to remove a variety of organic and inorganic pollutants from various source water. And we’ll show how batch and column experiments performed in a field-lab setting can be used in conjunction with diffusional models to quantitatively explore different treatment scenarios, for example through simulating system performance for water containing different levels of target pollutant(s), and the effects of varying contact time between water and sorptive media. (If you want to read ahead, a good place to start is our open-access paper just out this month in Water Research X entitled, “Modeling and experimental approaches for determining fluoride diffusion kinetics in bone char sorbent and prediction of packed-bed groundwater defluoridator performance.”)

I’m really looking forward to more regular and content-heavy posting in the weeks to come. It’s been great the past few months to have done a deep-dive into data analyses and journal-paper-writing. With one paper out and a couple more in the review process I can turn back to the fun work of writing for an audience with much broader experience and interests.

Thank you all again for your support and interest in this project. Let me know in the comments or by email if you have questions, comments, or special requests and I will do my best to respond.